Introduction of Huashida PE Vacuum Calibration&Insulation Jacket pipe Production Line

Four Series: Φ365-760mm, Φ855-1380mm, Φ960-1680mm, Φ1380-1880mm.

Core technology:

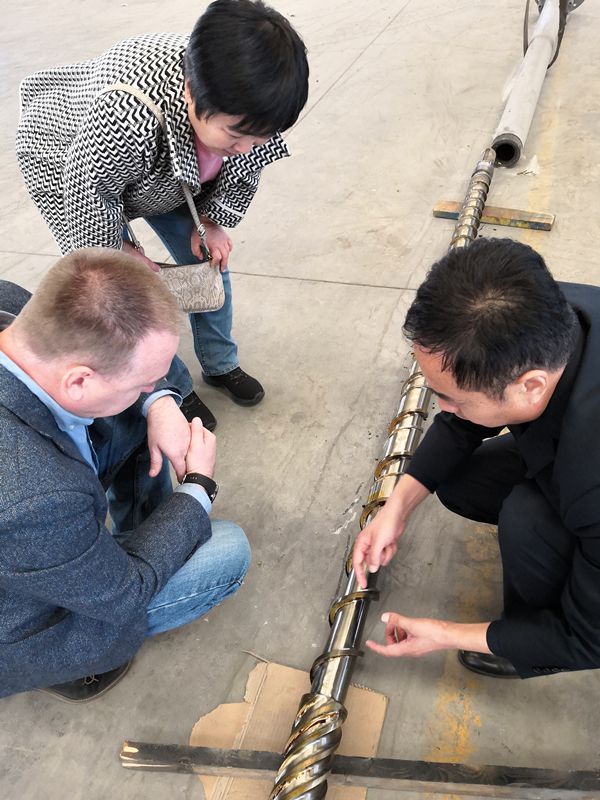

1. Screw: A new generation of solid-liquid phase separation screw technology is used. The screw is divided into forced feed section, melting solid-liquid phase separation section, confluence plasticization section, homogenization section and forced mixing section. The screw is designed with large aspect ratio, 33-38:1. The screw drum is designed with an extended forced feeding system. The inner wall of the screw drum is provided with feeding troughs of different structures to ensure the rapid compression and propulsion of materials. The lengthened forced cooling system is flanged to the high temperature screw, and there is a 1-3MM gap to prevent heat from conducting to the feeding section, so as to ensure rapid high-pressure and low-temperature propulsion of materials. The speed ratio of the gearbox is 16-8:1, which ensures the high speed of the screw and the high power kinetic energy system, so as to achieve high speed and high efficiency. SJ75/33 extrusion volume is 300-350 kg/h, SJ90/33 extrusion volume is 500-550 kg/h, SJ120/33 extrusion volume is 800-900 kg/h, SJ150/33 extrusion volume is 1200-1400 kg/h. The system has the advantages of high efficiency, high speed, high extrusion volume, good yield, long service life, stability and reliability.

www.hsdanticorrosion.com , hsdc@qdhsd.com , whatsapp/wechat: 008613963975523

Revi: Die Head Introduction of Huashida PE Vacuum Calibration&Insulation Jacket pipe Production Line

Next: Qingdao Huashida is a leading manufacturer of thermal insulation&anti-corrosion pipe equipment