ORDERING HOTLINE : +86-532-80999083

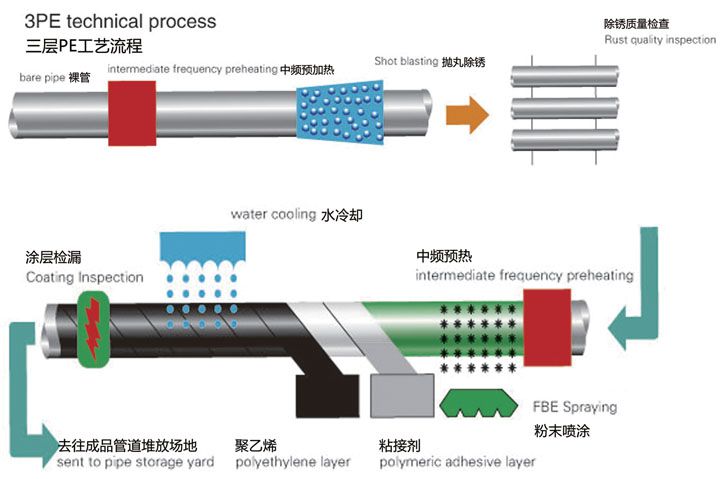

Huashida 3LPE steel pipe blasting&coating equipment can make water gas oil supplied pipeline dia. (32-3000mm),according to customers demand. The production line make internal and external shot blasting derusting,Dual Fusion Bonded Epoxy powder/liquide Coating & PE/PP film Wrapping ,End of PE grooving system and so on.

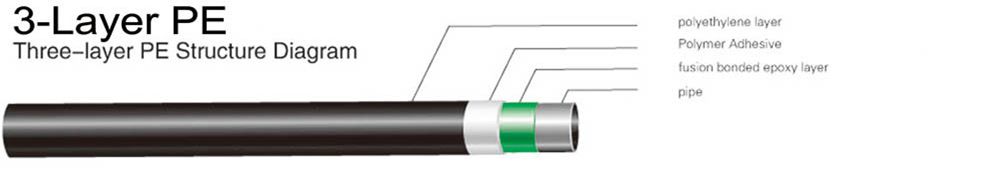

3 Layer PE Steel Pipe Anti-Corrosion Coating Machinery

3LPE coating line is to make anti-corrosion of kinds of steel pipes, such as single layer FBE, double layer FBE, double layer PE, double layer PP and 3PE. Outer protective layer of coated pipe has a high mechanical strength, excellent electrical insulation performance. The merits includes high degree of mechanization, process parameters stable, not pollute the environmen. It is to prolong the pipeline life of use from 5-10years to 50-100years.

Application

The three-layer PE process, with the epoxy powder coating as bottom layer, binding and bundling through polyethylene PE and adhesive, is widely used in anticorrosion of steel pipes, and applied to the oil, natural gas, chemical material, water pipelines.

Equipment Description

Composed of production line

-steel pipe conveyor system

-internal&external surface blasting system

-pipe dust removal system

-pipe heating system

-electrostatic FBE coating system

-adhesive and PE Layer wrapping system

-water cooling system

-end beveled system

-hydraulic and pneumatic system

-testing system

-electronic control system

.

Steel pipe conveyor system

1. Automatic conveyor adjustment as per pipe size controlled

2. Siemens PLC central control computer

3. Interactive human-computer interface screen

4. Customization according to user special require

5. Unified adjustment of opening and closing, unified adjustment of angle.

6. Each set of wheels is driven by independent power to expand the spiral angle of the conveyor, and the transmission angle can reach 30degrees.The transmission speed is adjustable from 0-6 meters.Adopt solid wide-surface tires, a single wheel with a load capacity of 2.5 tons,press-fit tires,no degumming, no cracking. The thickness of the glue layer is greater than 85 mm, the transmission is stable and reliable,and the safety guarantee for the long-term operation of the equipment.

Steel pipe heating equipment

Steel pipe heating equipment is used to heat pipes. It can preheat, heat and curing pipes with different technological requirements.It is used to heat the pipe from 40℃ to 60℃ before blasting, and to wipe off water, moisture and greasy dirt on the surface, which can meet the demands of rust removal.It includes intermediate burner heating and frequency heating (see intermediate frequency heating) form.The heating media of burner can be gas and diesel.Intermediate frequency heating system is mainly used to heat pipes to 180℃- 230℃ to meet the coating standard.

Steel pipe blow equipment

The internal blowing system is used to clean the dust, and sand inside the pipes by the draught fan, so that it can prevent the pollution when coating.The system includes pipe internal blowing carrier, dust collecting box, pulse back-blowing dust collector, live rotation roller, pipe stopper, etc. A set of filter-barrel type pulse back blowing dust collector is equipped on the dust collection box.

Dust treatment It is used to clean dust and abrasive on pipe surface after blasting and improve the adhesion of FBE.

Fusion Bonded Epoxy powder coating equipment and recovery system

The system includes stainless coating room, epoxy powder guns, powder coating controller, fluidization powder box,dual cyclone collecting structure,and pulse-blowback-cylinder dust catcher.

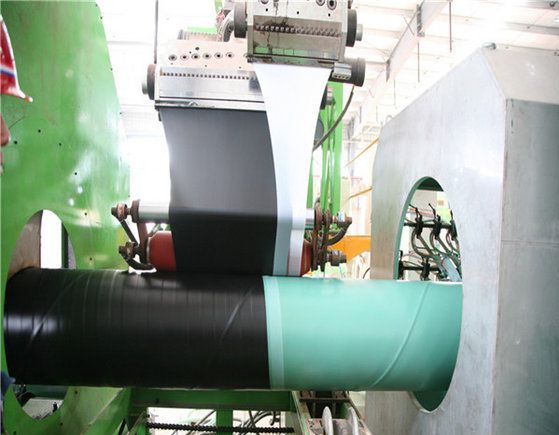

Extrusion system

It is used to extrude PE adhesive and PE protective coating, which are twined to the external wall of the pipes.The polyethylene protective coating can protect the epoxy powder coating.It can be divided into cladding type and twining type according to coating pattern and twining type can be divided into side type and upper type.

Steel pipe water spraying equipment

The water cooling system is used to cool heated piped rapidly to the temperature of 40℃-60℃, to protect its anticorrosion layer and protection layer.Water cooling system consists of water cooling room, water cooling tower, self-prime pump, centrifugal pump, pipeline, etc. There is a back water pond near cooling room.

Cutback machine

This device is used to remove pipe-end coating layer and then form a groove whose angle is below 30°, in order to joint easily.It is double-head high-efficient cutback machine. It is composed of steel brush, polishing motor, moving trolley, high efficiency dust collector etc.It is also equipped with lifting rotation roller, rocker arm etc.

Question & Answer:

Q1. What is Size of Pipe Dia. your equipment can produce ?

A: We can produce four main Model: Diameter of steel Pipe:48-219mm, 219-1220mm, 800-1600mm, 1000-2400mm

Q2. What is Descaling grade?

A: SA2.5

Q3. What is your anticorrosion coating standard?

A: It can meet SY/T0413-2002 ,GB/T23257-2009, German DIN 30670 , DIN 30678 and coating specification requirements from American Corrosion Association, and DNV . The product pipe fully complies with SY/T0315-2005 ,CNPC38-2002 "Technical specifications for double-layer fusion-bonded epoxy powder coating on buried steel pipe and Canada, American Corrosion Association standards

Q4. What is Delivery Time

A: 2-3monthes after deposit

Q5. Production output

A: It is different output capability as different pipe diameter, the Max. is 3 to 8 km/day,and annual processing capacity is 2 million square meters (Φ508 mm)

Q6. Coating thickness:

A: 80~800um

Q7. Which country did you sell your 3PE equipment?

A: We have produced nearly 50sets 3PE processing line at home and abroad. Such as Russia, Iran, UAE, Iran, India, Belarus, Kazakhstan and so on.

Q8. After-sales service:

A: Warranty period: Before delivery all the equipment must be trial operated to confirm the quantity perfectly.The warranty period is 12 months from the date of pick-up for mechanical part , and 6 months for the electrical part.

Service:The seller provides technical services and provides training and guidance to buyer operators.

| Environmental protection, energy conservation and emission reduction!Low energy consumption, high output, low scrap rate, saving materials and time! |

| Professional team for your service, detailed pre-sales technical consultation and perfect after-sales service to solve your worries. The seller would send technician to the buyer's factory to help installing and test the new machine and train people of the buyer. |

| 12 months from date of Bill of Lading.During this period, the seller will provide free service for all problems caused by quality of equipments, however except the problems caused by the buyer because of wrong operation. |

| Pre-sales and after-sales technical support,customer hotline:0086-532-80999083 |

Global Supplier

Huashida Machinery, with over 15 years' experience, is one of the professional hdpe pu thermal insulation jacket pipe extrusion production machine line manufacturers in China. Offering the customized service, we warmly welcome you to purchase the high qualified products from our factory.

Please fill out the form below and we will reply you back as soon as possible.