What is different between Side and upper type extruder for 3LPE coating line?

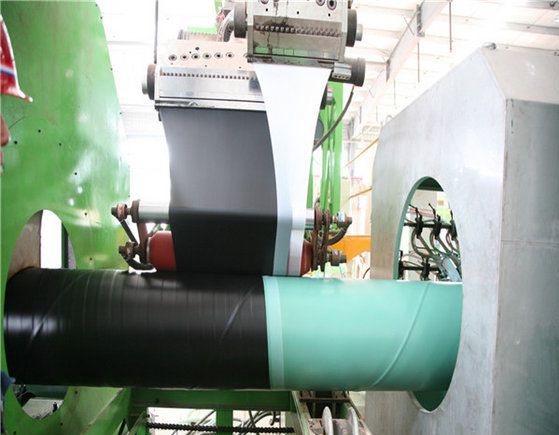

Side type, die is side blew pipes and the adhesive and polyethylene press rollers are directly blew pipes. The AD extruder and PE extruder are placed vertically with production line. They can move back and forward (AD extruder can move laterally) to adjust the angle between coating layer and steel pipes.

Upper type ,Two sets of extruder are placed on one side of production line. The extruder is vertical to production line. The extruders are placed on live platform and die and extruder can move up and down. Pressing roller and guide roller are separately placed on a live scaffold. This can help easily adjusting the extrusion and wrapping equipment according to different pipes and also adjusting the width of coating layer. It can not only ensure the uniformity of PE, but also save raw material.

Revi: Usage of heat shrinkable wraparound sleeve

Next: When use cladding type extrusion for 3LPE coating production line?